For more than 150 years, Brown-Forman Corporation has built a robust beverage alcohol product line that includes familiar brands such as Jack Daniel’s Tennessee Whiskey, Herradura, and Korbel. When a global process owner in Master Data Management needed to find an alternative to a repetitive, manual process, the firm’s Continuous Improvement Digital Transformation team used the robotic process automation (RPA) functionality in Microsoft Power Automate to convert a lower-value task to an automated process. The team has saved thousands of hours in the first seven months.

Sustaining a culture while driving transformation using Power Automate

It’s hard to get whiskey aging just right. It requires long-term planning, discernment, patience, and efficiency. For Brown-Forman Corporation, makers of Jack Daniel’s Tennessee Whisky and a host of other popular beverage alcohol brands—including Old Forester, Herradura, el Jimador, Korbel, Sonoma-Cutrer, Finlandia, Woodford Reserve, and Fords Gin—it also requires sustaining a culture rooted in 152 years of history while innovating to meet the demands of the future.

“We make whiskey today that we can’t touch for at least four years” says Jon Riehm, Lead Process Architect, Continuous Improvement Digital Transformation team for Brown-Forman Corporation. Yet, the company—with 5,200 employees on six continents—must also sustain its profitability and continue to improve efficiencies in a world defined by getting things done quickly.

Riehm says that long-term planning has helped Brown-Forman maintain a successful balance between honoring consumer preferences and company tradition while discerning the right places to streamline. It is foundational to the company’s longevity and success to date—and it’s the driving force for ongoing transformation.

Making processes more efficient, driving long-term success

Led by Riehm, The Continuous Improvement Digital Transformation team regularly evaluates company processes and works to identify more efficient ways to perform them. This helps add more value to the work, makes employees’ lives easier, and supports greater ongoing productivity. The team sees the processes in action, considers the details, and determines the best plan of action to meet both immediate and long-term needs.

Anna Richey leads the Master Data Management team within Global Business Solutions (GBS) for Brown-Forman Corporation. She saw a need to innovate the company’s vendor onboarding process and called on Riehm’s team for help.

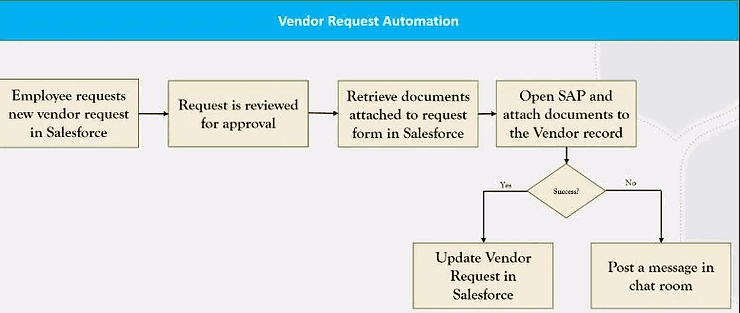

GBS owns the vendor onboarding process, which adds hundreds of new vendors monthly. The process is repetitive and time-consuming, requiring a dedicated employee to log into Salesforce, download the needed attachments (the number varies from 1 to 10 per record), log into SAP, find the vendor, and manually add the attachments that include W9s, 1099s, other tax documents, and bank details for every new vendor. The legacy process didn’t have native integrations between Salesforce and SAP for attachments. “Now, repeat that process 400 more times. There’s absolutely no value in this,” says Riehm. There were also possibilities for error.

Figure 1. The Vendor Request Automation steps.

Increasing job satisfaction, creating time for higher-value work To help GBS address these problems, Riehm and his team chose the robotic process automation (RPA) capability in Microsoft Power Automate. They were drawn to RPA for its ability to automate systems that didn’t have other integration points or had complex integrations. “One of the best things we found within Power Automate were the many built-in connectors to systems we already have—Salesforce, Workday, Google Workspace. They allowed us to hit the ground running by not having to worry about integrations with Power Automate and those systems. We were able to focus on just the RPA space instead of the other plumbing necessary to make RPA a success,” explains Riehm. The solution is also a huge time saver from a data consistency point of view because now the GBS team no longer has to worry about whether the master data specialist has migrated the data, as “the data is there, and it is correct. Now we have an automatic integration that runs real time instead of manually uploading hundreds of these at the end of the month,” he says. The records get added and all corresponding attachments come over automatically. “We don’t have to worry about touching the record more than once to get that data completely updated correctly in SAP,” adds Richey It also helps prevent errors and find missing data. For example, a member of Richey’s team had the manual task of tracking down missing data. “She had to remember to go back to each record, spend hours attaching the necessary documents, and risk attaching them to the wrong record,“ says Riehm. “Adding RPA to this process alleviated that mundane, error-prone manual task that had no value-add.” With newly gained time, Richey’s employee has been able to focus on identifying efficiencies in both the New Vendor and Vendor Change forms to help users get information correct at inception. She’s also been able to work more closely with a GBS-shared Google site project, build out a frequently asked questions (FAQ) document, and create training video content. Richey says, “This employee was ecstatic and felt immediate relief when we initiated the new automation process. Now she can work on projects she wouldn’t have had the time for with the legacy process.”

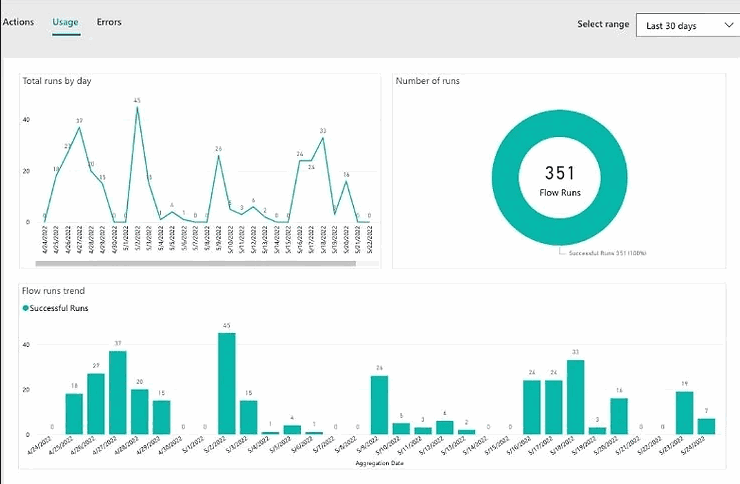

Figure 2. Power Automate interface showing flow run summaries and trends.

Figure 3. Labels of select brands in Brown-Forman’s beverage-alcohol collection.

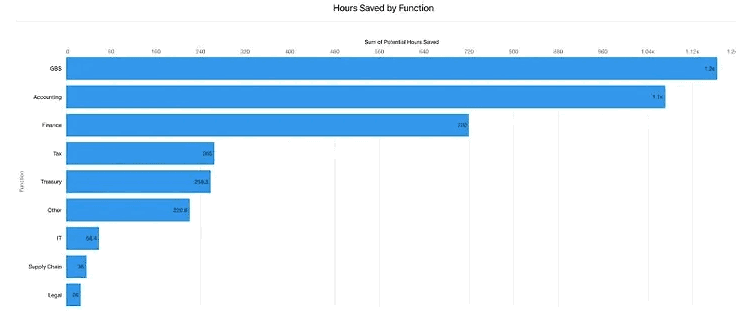

Saving time in the first seven months

“In our first 5 months as a team, we saved 1,800 hours for Brown-Forman. The three months after that we nearly doubled our hours saved which is crazy,” says Riehm. “We now have a tool that can achieve what we previously thought was impossible—or of such low priority—that we probably would have never addressed it.”

Figure 4. The teams at Brown-Forman where Power Automate has yielded time savings (shown in hours)

Working without limitations

Richey’s group is already working with the Continuous Improvement Digital Transformation team on other projects in the vendor space. The team is considering using automation as part of the general ledger (GL) as Richey’s group also deals with master data in that space. Her team has run an RPA process for table updates. “The benefit is immense,” she says. “I hope to be able to bring automation to that process. It changes exactly how we work and it’s a beautiful thing.”

Riehm believes Brown-Forman is still in the infancy of what’s possible with RPA, and that bodes well for the future. “I’ve been happily surprised at how capable Power Automate is,” he says. “I have not come across a task yet where there was a technical limitation, which is impressive. A lot of people are requesting automation from our team. I’m sitting with them, seeing their process, thinking about how we would solve it, and usually the answer is, let’s use Power Automate.”

“One of the best things we found within Power Automate were the many built-in connectors to systems we already have—Salesforce, Workday, Google Workspace. They allowed us to hit the ground running by not having to worry about integrations with Power Automate and those systems.”- Jon Riehm: Lead Process Architect, Continuous Improvement Digital Transformation